SLM Process Monitoring

During my master thesis, I worked on monitoring a SLM (Selective Laser Melting) process with a thermographic camera. By solving the Heat equation, with simplifyed boundary conditions, I was able to aproximate the heat flow after melting the powder. So, I was able to distinguish errors during the SLM-process e.g. delamination by measuring the cool down curve of the process-zone.

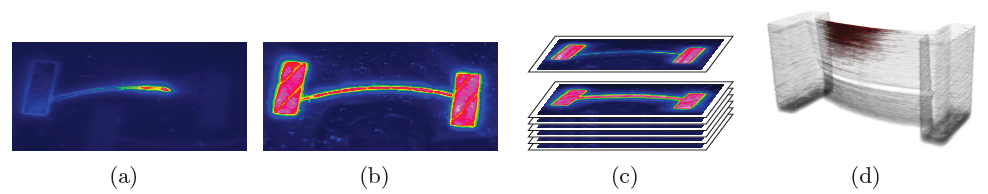

(a) Temperature measurement in the process; (b) Generated indicator image (in this example the maximum); (c) saving one indicator image every Layer; (d) using the Image stack to post evaluate the process like a CT scan.

My master theses (German)

[Masterarbeit_Zeugner.pdf (5MB)] Thermografische Charakterisierung eines Laserstrahlschmelzprozesses bei MetallwerkstoffenPapers

- Harald Krauss, Thomas Zeugner, Michael F. Zäh, Thermographic process monitoring in powderbed based additive manufacturing, AIP Conference Proceedings, 1650, 177-183 (2015), http://dx.doi.org/10.1063/1.4914608.

- Harald Krauss, Thomas Zeugner, Michael F. Zäh, Layerwise Monitoring of the Selective Laser Melting Process by Thermography, Physics Procedia, Volume 56, 2014, Pages 64-71, ISSN 1875-3892, http://dx.doi.org/10.1016/j.phpro.2014.08.097.

- Harald Krauss, Thomas Zeugner, Michael F. Zäh, Detecting process irregularities in selective laser melting by thermography, Fraunhofer Verlag, DDMC 2014.